MPH1

SINGLE WALL stainless steel

MPH1 is the innovative single-wall stainless steel metal chimney that features the “click-clack” system of jointing patented CANNA srl. This unique system in the world represents absolute added value and ensures significant advantages such as:

Superior safety, certified up to Class H1-5000Pa

Installation planned even without clamp

Faster and safer installation

The MPH1 Metal Chimney is available in the following standard diameters: 80, 100, 120, 130, 140, 150, 160, 180, 200, 220, 250, 270, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800, 850, 900, 950, 1000 … over on request

Applications

Exhaust gases evacuation from generators of all types (fireplaces, stoves, boilers in single or collective systems, thermal power plants …; from 40 ° C in conditions of high condensation to temperatures higher than 700 ° C, and beyond, in the presence of strong dilations, also resistant to thermal shock from soot fire at 1000 °C.

New flue systems and renovation of old ducts for flue ducting.

Air suction in artisan workshops and industrial production lines.

Steam evacuation in the industrial kitchen sector for catering and air exchange in public buildings.

The patented CANNA srl jointing system gives added value to the MP series, offering the advantage of maximum static stability and tightness to exhaust gases.

The joints, made with the best technology, automatically by expansion with external mold, guarantee a very tight jointing tolerance and therefore sealing conditions higher than the standard (even up to class H1 with 5000 Pa, against 200 Pa of class P1 in which classifies most of the products), thanks also to the use of the H 12mm silicone gasket positioned in the special seat.

Technical Information

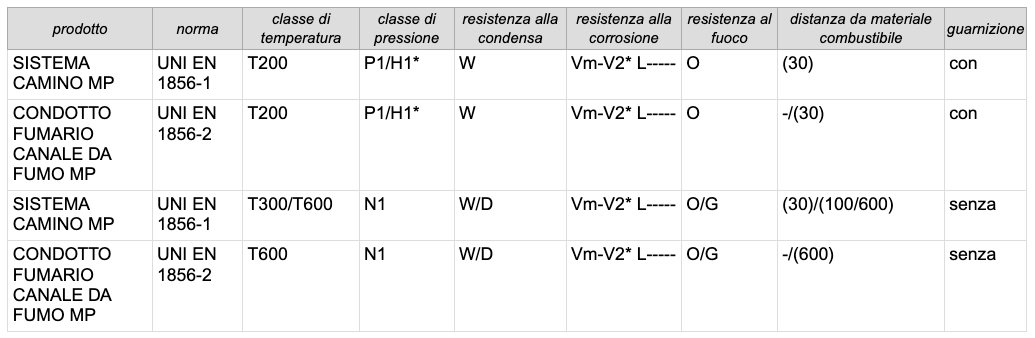

How to read it:

METAL CHIMNEY SYSTEM: exhaust gases evacuation system consisting of one or more walls composed of elements of the same series

METAL FLUE LINER: inner wall of a metal chimney, in contact with the exhaust gases

CONNECTING FLUE PIPE: connection between generator and metal chimney or duct, usually inclined or horizontal

Operating temperature T200-T300-T600 (tests performed at reference Temp + 50 ° C and + 100 ° C for T600)

Pressure Class P1 positive pressure 200 Pa; N1 press. Negative 40 Pa; H1 positive pressure 5000 Pa

Operating condition with / without condensation: W / D

Vm, L—– corrosion in relation to the material declared on delivery with a certificate from the steel mill of origin

V2 laboratory corrosion test for use with gaseous, liquid, solid fuel

Soot Fire Resistance (Thermal Shock 1000 ° C-30 min., G = YES; O = NO, due to the presence of the gasket)

(—) distance in mm from combustible materials to be respected

(T600-H1): testing phase passed, pending formal certificate issue

*: consult the technical office for more information

Butt-to-head automatic microplasma WELDING without adding of material with anticorrosive process in a closed atmosphere protected by inert gas

• JOINT with CLICK-CLACK SYSTEM, with a superior safety feature, even without a clamp with considerable savings in purchase and installation times; exclusive CANNA srl patent – Ing. Morelli L.

• T90 ° extruded for the whole line from D80 to D200 for generators and stoves

• Heat resistant triple lip silicone SEAL for an optimal seal even in class H1 (25 times higher than P1); class N1 without gasket

• CE marking and FPC FACTORY PROCESS CONTROL with the accredited and severe German organism TUV of MUNCHEN

First quality grade INOX AISI 316 L BA (polished finish) 0.5 mm for diameters from 80 to 180 mm, for generators and stoves

First quality grade INOX AISI 316 L BA (polished finish) 0.6 for diameters greater than D200 up to D500 (UNI 11278 standard: the use of 304 for exhaust gases evacuation systems is prohibited), intended for high temperatures such as fireplaces, whose strong thermal expansions need greater construction strength, 0.8 – 1 mm for larger diameters or in relation to specific uses

The countless applications in prestigious architectural contexts and the particular sensitivity of the company to the aesthetic aspect, as well as functional, make CANNA srl with its DESIGN service the right interlocutor for any particular construction.

INSULATION NOTE:it is always recommended to externally insulate any metal chimney, metal liner or connecting flue pipe with the special aluminized mineral fiber coverings; the insulation allows the evacuated of exhaust gases to preserve the temperature by reducing condensation and unburnt deposits (soot) and increasing the draft.