DOUBLE WALL

DP ISOAIR

Diameters:80/100 – 80/130, 100/120 – 100/150, 120/140, 130/150 – 130/180, 140/160, 150/160 – 150/200, 160/180, 180/200

Applications:

- Exhaust gases evacuation at low temperatures from single generators such as condensing boilers in single or collective systems, pellet stoves

- Situations of dimensional difficulties with prohibitive architectural sizes for DP 25 or DP 50, but only with low temperatures

- Need to camouflage exposed external flue pipes assimilating them to common rain downpipes

With the growing diffusion of condensing generators, it is even more important to talk about the insulation of heat and exhaust gases. In some cases it is impossible to perform the correct insulation for the dimensions that the DP 25 and DP 50 double insulated standard wall metal chimney series have; CANNA srl Technical Office has thus introduced a new series: the DP ISOAIR.

The DP ISOAIR seriesis characterized by a lower level of insulation than the DP 25 or 50, because it has a thin air interspace (10 – 15 – 25 mm thickness)present between the external and internal wall, which insulates this the latter in contact with the exhaust gases, however it also guarantees a minimum thermal resistance R17, useful for improving draft conditions.

A designed assembly system between the two walls creates a static air interspace which, by preventing the convective motions of air circulation and at the same time allowing the removal of any internal parasitic condensation, make the layer of the latter insulating.

The TECHNICAL OFFICE recommends the use of the DPISOAIR series only for generators operating with low exhuast temperatures (condensing generators or pellet stoves); for higher temperatures it is possible to insert an insulating layer in non-carcinogenic natural ceramic fiber in the air interspace in order to improve its thermal insulation behavior even in the presence of higher temperatures.

Technical Information

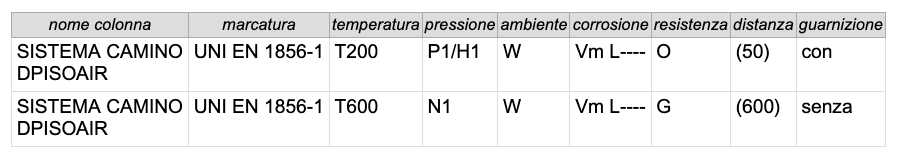

How to read it:

METAL CHIMNEY SYSTEM: exhaust gases evacuation system consisting of one or more walls composed of elements of the same series

Operating temperature T200 (tests performed at reference Temp + 50 ° C)

Pressure Class P1 positive pressure 200 Pa; N1 press. Negative 40 Pa; H1 positive pressure 5000 Pa

Operating Condition with Wet condensation

Vm, L—- corrosion in relation to the material declared on delivery with a certificate from the steel mill of origin

Soot Fire Resistance (Thermal Shock 1000 ° C-30 min., G = YES, O = NO, due to the presence of the gasket)

(—) distance in mm from combustible materials to be respected

- Butt-to-head automatic microplasma WELDINGwithout adding of material with anti-corrosive process in a closed atmosphere protected by inert gas

- ASSEMBLYof internal and external wall with radial pressure system without stagnation areas for internalparasitic condensation

- Heat resistant triple lip silicone GASKET for an optimal tightness even in class P1

- CE marking and FPC FACTORY PROCESS CONTROL with the accredited and prestigious German body TUV of MUNCHEN

INTERNAL WALL:

- First quality grade stainless steel AISI 316 L BA (polished finish) thickness 0.5 mm

INSULATION:

- Insulation with static air interspacethickness 10 – 15 mm

EXTERNAL WALL:

Options:

- First quality grade stainless steel AISI 304 BA (polished finish) 0.5 mm thickness

- COPPER purity grade CU-DHP 99.9% thickness NOT LESS THAN 0.6 mm

- Brass 0.6 mm

- Stainless steel AISI 304 painted in RAL colors of your choice (for quantities)