DOUBLE WALL

DP25TECH

Diameters:80/130, 100/150, 130/180, 150/200, 200/250, 220/270, 250/300, 300/350,… for larger diameters see DP50 (25 mm thickness option on request)

Applications

- Exhaust gases evacuation from of all types (fireplaces, stoves, boilers in single or collective systems, thermal power plants …), from 40 ° C in conditions of high condensation to temperatures higher than 700 ° C, and beyond, in the presence of strong dilations, also resistant to thermal shock from soot fire at 1000 ° C

- Aspiration and evacuation of vapors for professional kitchen sector for catering and air exchange in public buildings with the need to keep noise levels and the presence of condensation to minimum.

With theDOUBLE WALL DP25 CANNA srl it is possible to obtain a notable improvement in the exhaust conditions of the flue gases, thanks to the designed technical and constructional characteristicsof the CE UNI 1856-1certified product.

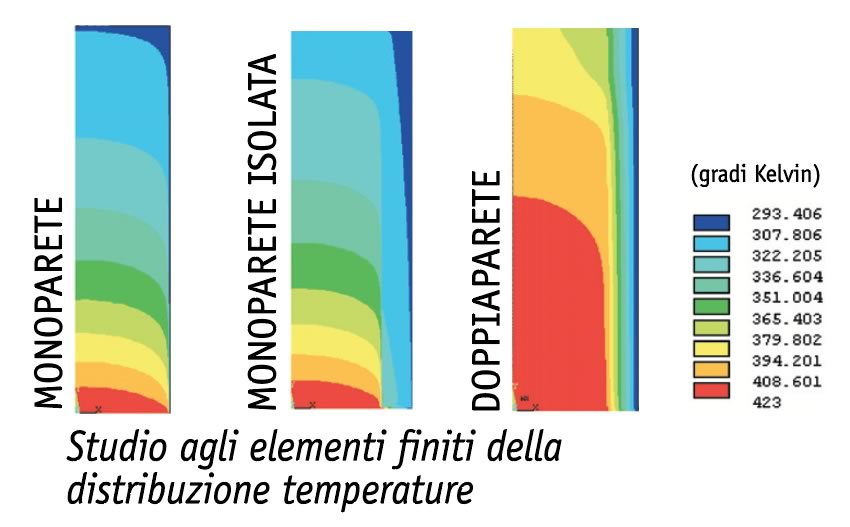

The speed and temperature of the exhaust gases, higher in the double wall (as also demonstrated by the analysis of the finite elements of the distribution of the temperatures), facilitate the evacuation of the gases, reducing the formation of acid condensate, harmful to the system, and soot build-up.

The absence of closing flanges allows to eliminate harmful thermal bridges between internal and external wall to the advantage of insulation; the consequent double joint of 50 mm, both for the external and internal wall, hinders possible infiltrations from the outside and improves mechanically the joint ensuring superior mechanical strength, for greater resistance to loads such as wind or cantilever elements.

The DP50 series is distinguished by the increased thickness of the insulation, from 25 to 50 mm, and is applied for the evacuation of gases from particularly high temperatures and for the larger diameters of the series, greater than D300, with compensation for the relative dilations .

Technical Information

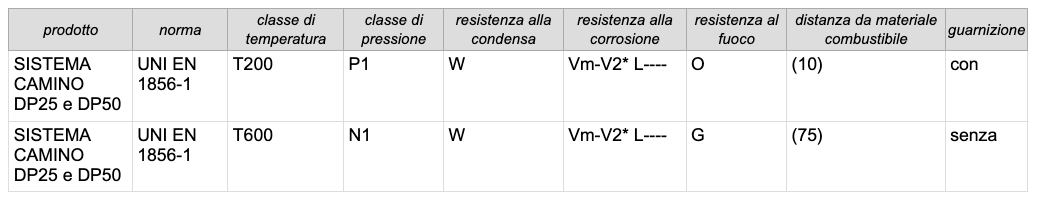

How to read it:

METAL CHIMNEY SYSTEM: exhaust gases evacuation system consisting of one or more walls composed of elements of the same series

Operating temperature T200-T600(tests performed at reference Temp + 50 ° C and + 100 ° C for T600)

Pressure Class P1 positive pressure 200 Pa; N1 press. Negative 40 Pa

Operating allowed in wet W (with condensation) and without

Vm, L—– corrosion in relation to the material declared on delivery with a certificate from the steel mill of origin

V2laboratory corrosion test for use with gaseous, liquid, solid fuel

Soot Fire Resistance (Thermal Shock 1000 ° C-30 min., G = YES, O = NO, due to the presence of the gasket)

(—) distance in mm from combustible materials to be respected

(T600): testing phase passed, pending formal certificate issue

*: consult the technical office for more information

- Butt-to-head automatic microplasma WELDINGwithout adding of material with anti-corrosive process in a closed atmosphere protected by inert gas

- • T90 °extruded for the whole line from D80 to D200 for generators and stoves

- ASSEMBLY of internal and external wall with radial jointing system without thermal bridges and internal parasite condensation

- Heat resistant triple lip silicone GASKETfor an optimal seal even in class P1, N1 without gasket

- CE marking and FPC FACTORY PROCESS CONTROL with the accredited and severe German organismTUV of MUNCHEN

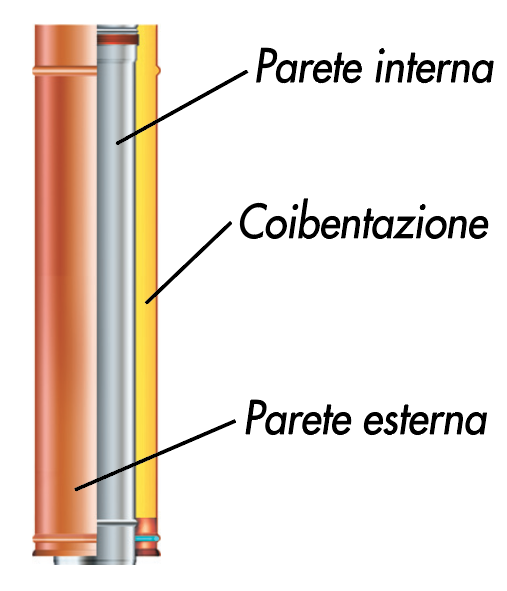

INTERNAL WALL:

- First quality grade stainless steel AISI 316 L BA (polished finish) 0.5 mm for internal diameters from D80 to D300 mm (0.6 mm for larger diameters / on request), 0.8 – 1 mm for larger diameters and in relation to use

- First quality grade stainless steelINOX AISI 304 BA (polished finish) on request for suction / air treatment application.

INSULATION:

- Insulation in certified high density mineral fiber (100-120 kg / mc) cut flush from block for maximum density and quality uniformity, in the standard thickness of 25 mm (others at the request of the client or for special applications)

EXTERNAL WALL:

Options:

- First quality grade stainless steel INOX AISI 304 BA (glossy finish) thickness 0.5 mm up to the internal diameter D300, 0.6 mm for larger diameters, 0.8 -1 mm for larger diameters and in relation to use

- COPPER purity grade CU-DHP 99.9% thickness NOT LESS THAN 0.6 mm

- Brass 0.6 mm

- Stainless steel AISI 304 painted in RAL colors of your choice (for quantities)